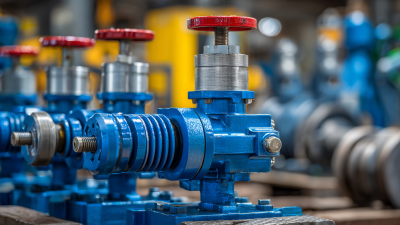

In the ever-evolving landscape of global procurement, selecting the right butterfly valve is critical to ensuring operational efficiency and reliability in various industrial applications. With the global valve market projected to reach approximately $92 billion by 2025, as reported by MarketsandMarkets, it is essential for procurement professionals to understand the intricacies involved in choosing the most suitable valve type. Butterfly valves, known for their lightweight design and space-saving capabilities, are increasingly favored in sectors such as water treatment, oil and gas, and HVAC systems. However, challenges such as material compatibility, sealing performance, and maintenance requirements must be carefully considered to mitigate potential issues down the line. This guide aims to delineate the common problems associated with butterfly valves and provide actionable insights for making informed procurement decisions.

When it comes to selecting the right butterfly valve for your global procurement needs, understanding the different types available and their specific applications is crucial. Butterfly valves are generally classified into various categories, such as resilient seated, high-performance, and triple offset valves. Resilient seated butterfly valves are commonly used for low-pressure applications, offering a cost-effective solution for industries such as water treatment. In contrast, high-performance butterfly valves are designed for higher-pressure scenarios, making them ideal for oil and gas pipelines where reliability and durability are paramount.

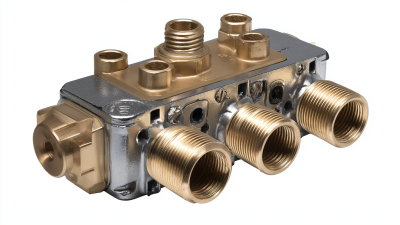

In addition to these types, it’s essential to consider the materials used in butterfly valve construction, as they can greatly affect performance in diverse global markets. For example, stainless steel valves are preferred in corrosive environments, while cast iron valves are suitable for less aggressive applications. Furthermore, understanding the specific requirements of local markets, including compliance with industry standards and regulations, will guide procurement decisions. By aligning your choice of butterfly valve with these considerations, you can ensure optimal performance and longevity in your infrastructure projects worldwide.

| Valve Type | Diameter Range (mm) | Pressure Rating (PN) | Material Options | Applications |

|---|---|---|---|---|

| Wafer Butterfly Valve | 50 - 1200 | PN10, PN16 | Ductile Iron, Stainless Steel | Water Supply, HVAC |

| Lug Butterfly Valve | 65 - 1400 | PN10, PN16 | Carbon Steel, Stainless Steel | Chemical Processing, Oil & Gas |

| Double Flanged Butterfly Valve | 300 - 2400 | PN6, PN10, PN16 | Steel, PVC | Wastewater Treatment, Mining |

| Concentric Butterfly Valve | 25 - 600 | PN10, PN16 | Copper, Bronze | Food Processing, Pharmaceutical |

When it comes to selecting the right butterfly valve for global procurement,

performance data serves as a

critical metric in the decision-making process. Understanding how different

butterfly valves perform under various conditions—such as pressure, temperature,

and flow rate—can help businesses choose the most suitable product for their

specific applications. Performance data not only reflects the reliability and

efficiency of the valve but also indicates its longevity, thereby influencing

lifecycle costs and maintenance needs.

Furthermore, comparing performance metrics across different manufacturers can shed

light on which valves consistently meet industry standards and regulatory

requirements. For instance, pressure

drop, response time, and

leakage rates can vary

significantly among products. Procurement teams must analyze these parameters to

ensure compliance with operational demands and to optimize system performance. By

using performance data as a benchmarking tool, organizations can make informed choices, ultimately

leading to cost savings

and enhanced reliability in their fluid control systems.

When selecting the right butterfly valve for your procurement needs, material choice is paramount. Different industries require valves made from materials that meet specific durability and performance standards. For instance, according to the 2022 Valve Manufacturer’s Association report, stainless steel valves are preferred in chemical processing due to their resistance to corrosion and high temperatures. In contrast, cast iron valves may be more suitable for water distribution systems where cost-effectiveness is a priority, yet they may not hold up as well in harsher environments.

Tips: Always assess the environmental conditions the valve will be exposed to; corrosive substances, extreme temperatures, and pressure levels can significantly influence the material's longevity. Additionally, consider the regulatory standards specific to your industry, as compliance can affect your valve's operational life and reliability.

Another important factor is the valve's maintenance requirements, which can vary based on the material used. For example, plastic butterfly valves are lightweight and resistant to certain chemicals, but they may require more frequent inspections compared to metal valves. The right choice not only impacts the longevity of the valve but also the overall efficiency of your operations.

Tips: Request data sheets and warranties from manufacturers to better understand the expected performance metrics for different materials under varied conditions. Engaging with industry experts can provide insights into long-term cost savings associated with material choices, ultimately supporting more informed procurement decisions.

When it comes to procuring butterfly valves, a comprehensive cost-benefit analysis is essential to strike the right balance between quality and price. Butterfly valves are a critical component in numerous industrial applications, and their performance can significantly impact operational efficiency and safety. Therefore, while pricing is undoubtedly a significant factor, overlooking the quality aspects can lead to higher maintenance costs and operational downtimes in the long run. It's crucial to evaluate how the initial purchase cost aligns with the long-term value offered by the valve in terms of durability, efficiency, and reliability.

One effective approach to this analysis is to consider the total cost of ownership (TCO), which includes not just the purchase price but also installation, maintenance, and potential downtime costs. High-quality butterfly valves may come with a higher upfront cost, but they often offer improved sealing and reduced wear, leading to savings on maintenance and replacements over time. On the other hand, lower-cost options may initially seem attractive but can result in greater expenses down the line. By carefully assessing both quality and price, procurement professionals can make informed decisions that support both budget constraints and operational goals.

When it comes to selecting the right butterfly valve for your global procurement needs, regulatory compliance is a paramount concern. Different industries, from water treatment to oil and gas, face unique standards dictated by regional and international guidelines. Understanding these regulations not only ensures the safety and reliability of your operations but also guarantees that your products meet the required performance standards across varying applications.

Navigating these compliance requirements is essential. For instance, the American Petroleum Institute (API) outlines strict criteria for butterfly valves used in the oil and gas sector, ensuring they can withstand high pressures and corrosive environments. Similarly, the European Union has specific directives that influence valve design and materials, particularly regarding sustainability and environmental impact. By staying informed about these regulations, procurement professionals can make more informed decisions, thereby minimizing risks and enabling smoother operations.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields