In the ever-evolving industrial landscape, selecting the appropriate ball valve is crucial for ensuring efficiency and safety in systems that handle liquids and gases. According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach $12.3 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth underscores the increasing reliance on reliable flow control mechanisms across various sectors, including oil and gas, water and wastewater, and food and beverage industries. As industries strive for higher efficiency and stricter compliance with safety regulations, understanding the different types of ball valves and their applications becomes essential. This ultimate guide will provide you with the knowledge needed to make an informed decision, ensuring you choose the right ball valve tailored to your specific industrial needs.

When it comes to industrial applications, selecting the right ball valve is crucial for ensuring optimal performance and reliability. Ball valves come in various types, each designed to meet specific needs within different industrial environments. The most common types include full port, reduced port, and V-port ball valves. Full port ball valves allow unobstructed flow, making them ideal for applications requiring high flow rates. In contrast, reduced port ball valves have a smaller opening, which can lead to pressure drops but are suitable for applications where space and cost are considerations.

Another significant type is the V-port ball valve, which is engineered for throttling applications. The unique V-shaped opening allows for precise flow control, making it invaluable in processes where fluid regulation is essential. Additionally, there are specialized valves such as trunnion-mounted ball valves, which are designed for high-pressure and high-temperature applications, providing stability and strength. Understanding the different types of ball valves and their specific functionalities is vital for making an informed choice that aligns with your industrial needs.

This chart illustrates the relative usage of different types of ball valves in various industrial applications, highlighting how each valve aligns with specific industrial needs.

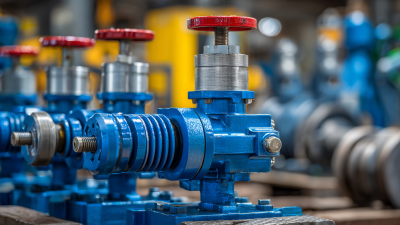

When it comes to high-pressure applications in industrial settings, trunnion-mounted ball valves stand out for their exceptional performance and reliability. Unlike traditional floating ball valves, trunnion-mounted designs are anchored at both the top and bottom, providing greater stability and minimizing seat wear. This stability is crucial in high-pressure environments where the risk of valve failure can lead to significant operational disruptions.

When it comes to high-pressure applications in industrial settings, trunnion-mounted ball valves stand out for their exceptional performance and reliability. Unlike traditional floating ball valves, trunnion-mounted designs are anchored at both the top and bottom, providing greater stability and minimizing seat wear. This stability is crucial in high-pressure environments where the risk of valve failure can lead to significant operational disruptions.

Tip: When selecting a trunnion-mounted ball valve, consider the flow characteristics and pressure rating necessary for your application. Ensuring the valve can handle the intended pressure will prevent premature wear and potential failures.

Trunnion-mounted ball valves are also known for their low torque requirements, which makes them easier to operate and maintain. This feature translates into lower energy consumption and reduced costs over time. Additionally, they offer enhanced sealing capabilities, making them ideal for applications involving hazardous fluids where leaks can pose serious safety risks.

Tip: Ensure regular maintenance and inspection of trunnion-mounted ball valves to prolong their lifespan and maintain the integrity of your system. A proactive approach can help identify wear or other issues before they escalate into costly problems.

Floating ball valves play a crucial role in process control and efficiency in various industrial applications. These valves are designed with a ball that "floats" within the valve body, allowing it to seal tightly against the seat when pressure is applied. This floating mechanism ensures that the valve provides a reliable shut-off in high-pressure systems, making it ideal for applications where leakage can lead to significant operational issues. The ability of floating ball valves to maintain a tight seal under fluctuating pressure conditions enhances their effectiveness in process control.

Moreover, the simplicity of design in floating ball valves translates into ease of operation and maintenance. With fewer moving parts compared to other valve types, they require less frequent servicing, leading to reduced downtime and increased operational efficiency. Industries ranging from oil and gas to water treatment benefit from the reduced risk of failure and the ability to maintain precise control over fluid flow. As a result, integrating floating ball valves into industrial systems not only streamlines operations but also improves overall process efficiency by minimizing wastage and ensuring optimal performance.

| Valve Type | Size (inch) | Pressure Rating (PSI) | Material | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Floating Ball Valve | 1 | 150 | Carbon Steel | -20 to 250 | Water, Oil, Gas |

| Full Port Ball Valve | 2 | 300 | Stainless Steel | -50 to 400 | Chemical Processing |

| Trunnion Mounted Ball Valve | 3 | 600 | Alloy Steel | -40 to 450 | Oil and Gas, Power Generation |

| PVC Ball Valve | 1.5 | 100 | PVC | -15 to 140 | Water Supply, Irrigation |

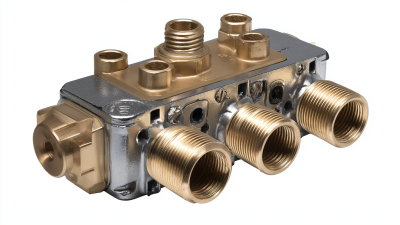

When it comes to selecting a ball valve for chemical handling, the material plays a crucial role. Two popular options are stainless steel and PVC. Stainless steel ball valves are renowned for their durability and resistance to corrosion, making them ideal for harsh chemicals and high-pressure applications. They can withstand extreme temperatures and provide a tight seal, ensuring safety and efficiency in industrial processes.

On the other hand, PVC ball valves offer a lightweight, cost-effective alternative. They are highly resistant to a wide range of chemicals, particularly acids and caustics, making them suitable for less demanding applications. However, PVC may not hold up as well under high temperatures or pressures compared to stainless steel.

**Tip:** When choosing between stainless steel and PVC, consider the specific chemicals being handled and the operational conditions. Conducting a thorough assessment of your environment will help in making the right decision.

**Tip:** Always consult with manufacturers or suppliers for detailed specifications and compatibility charts to ensure the valve you choose meets the requirements of your system. This diligence will help prevent potential leaks or failures down the line.

When it comes to industrial operations, making the right investment in high-quality ball valves can significantly impact energy efficiency and overall cost savings in the long run. While cheaper alternatives may seem appealing at first glance, they often lead to increased maintenance costs, inefficiencies, and potentially higher energy consumption. This is particularly relevant in industries such as cement production, where energy efficiency is a critical factor in reducing operational expenses.

By conducting a thorough cost-benefit analysis, companies can better understand the long-term savings associated with investing in quality ball valves. Energy-efficient technologies, such as properly selected valves, can improve system performance and lower carbon dioxide emissions significantly. This aligns with the findings of recent studies that indicate the importance of quality components in achieving energy savings within industrial settings. Investing in the right valve not only assures operational reliability but also supports sustainability goals, ultimately providing a greater return on investment over time.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields