In the ever-evolving landscape of hydraulic systems, selecting the appropriate hydraulic check valve is crucial for ensuring optimal performance and reliability. According to a recent report by Market Research Future, the global hydraulic valve market is projected to reach over $18 billion by 2027, highlighting the significant role these components play in various industrial applications. The efficiency and longevity of hydraulic systems largely depend on the quality of the check valves, as they prevent backflow and maintain pressure. Moreover, effective after-sales service and reasonable maintenance costs can significantly influence decision-making for manufacturers and engineers alike. This blog will explore top strategies for choosing the best hydraulic check valve tailored to your specific needs, ensuring that you not only enhance system efficiency but also manage operational costs effectively.

When selecting a hydraulic check valve, the importance of after-sales service cannot be overstated. Data-driven insights reveal that facilities that prioritize after-sales support experience a 20% reduction in operational downtime. This statistic underscores the necessity of a responsive service network, as prompt maintenance and trouble-shooting can significantly enhance the life expectancy of hydraulic systems. According to a report by the Fluid Power Journal, companies that engage with suppliers offering strong after-sales support report a 15% improvement in overall efficiency.

Moreover, selecting a hydraulic check valve involves not only evaluating technical specifications but also the level of after-sales service provided. A survey conducted by Hydraulics & Pneumatics indicated that 78% of industry professionals cited reliable after-sales service as a critical factor in their decision-making process. This includes access to technical support and availability of replacement parts, which are fundamental for minimizing downtime. By partnering with suppliers who emphasize comprehensive after-sales services, companies can secure long-term value and operational reliability in their hydraulic systems.

When selecting a hydraulic check valve, understanding the long-term maintenance expenses tied to quality is crucial. High-quality valves often incur higher upfront costs but can significantly reduce repair and replacement expenses over time. According to industry reports, investing in premium valves can lower maintenance costs by up to 30% due to their durability and reliability, minimizing downtime and disruption in operations.

One key consideration is the material and manufacturing quality. Valves manufactured in regions known for strict quality standards and advanced technology tend to outperform those made in less regulated environments. It’s also essential to assess the manufacturer's reputation and track record for providing components suitable for demanding conditions.

**Tip 1:** Opt for valves that come with a comprehensive warranty, as this can help mitigate potential repair costs.

**Tip 2:** Regularly inspect and maintain your valves to catch issues early, which can prolong their lifespan and reduce unexpected expenses.

In addition, it's advisable to keep a close eye on the performance of your piping system, especially during extreme weather conditions, to avoid costly repairs related to frozen or burst pipes. Investing in high-quality components now can save you substantial amounts in the future.

| Valve Type | Material | Max Pressure (bar) | Repair Cost ($) | Expected Lifespan (Years) | Maintenance Frequency (per year) |

|---|---|---|---|---|---|

| Spring Check Valve | Cast Iron | 16 | 200 | 10 | 1 |

| Ball Check Valve | Stainless Steel | 25 | 150 | 20 | 0.5 |

| Swing Check Valve | Carbon Steel | 20 | 250 | 15 | 1.5 |

| Diaphragm Check Valve | Plastic | 10 | 100 | 8 | 2 |

| Silent Check Valve | Brass | 30 | 80 | 12 | 1 |

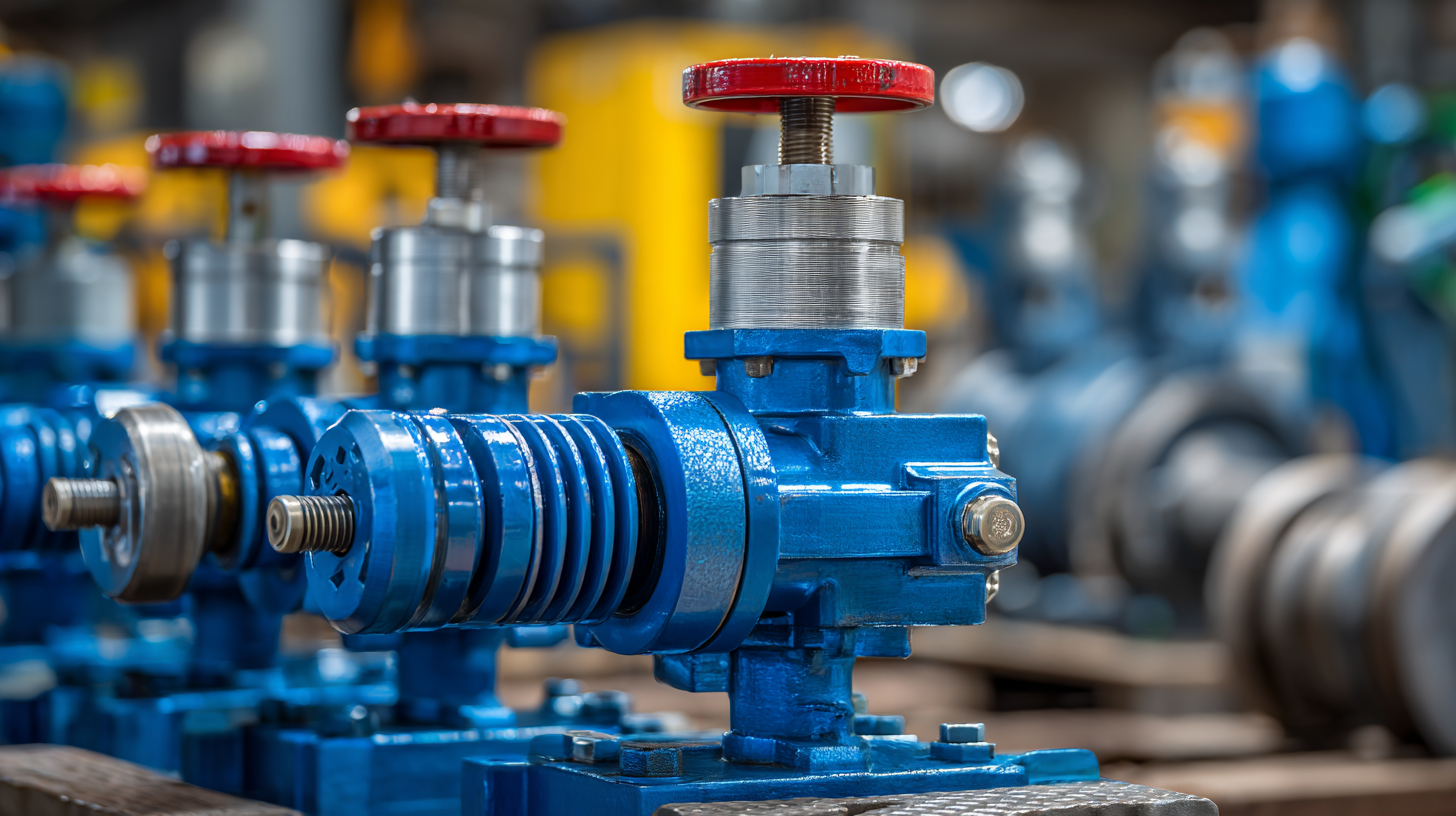

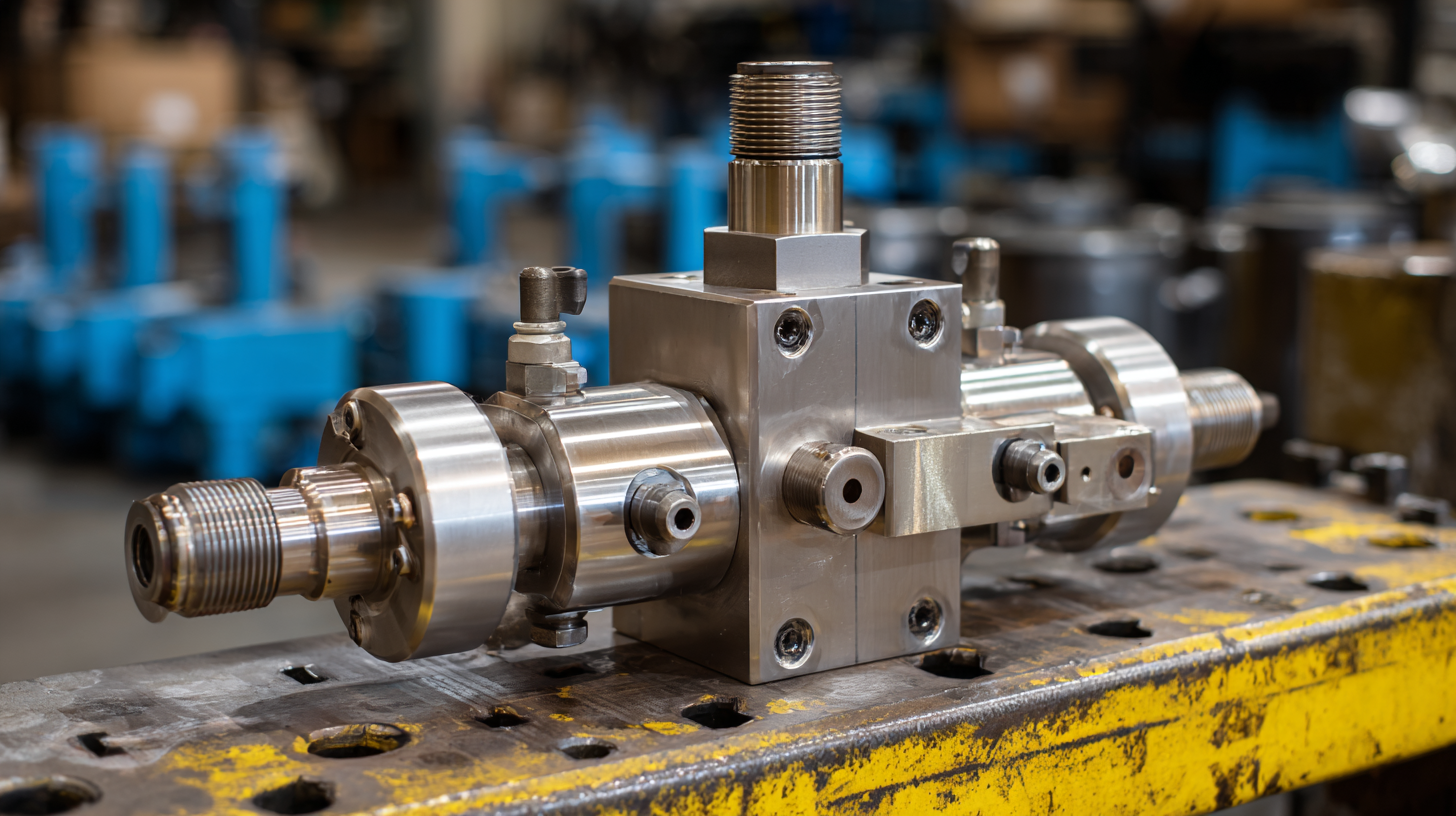

When selecting hydraulic check valves, several key factors can significantly influence their performance and longevity.

First, the valve material is crucial; choosing the right material can prevent corrosion and wear, which are common issues faced in various hydraulic systems. For instance, stainless steel is often preferred for its resistance to rust, especially in demanding environments. According to the Hydraulic Institute, the improper selection of materials can lead to up to 25% of system failures.

First, the valve material is crucial; choosing the right material can prevent corrosion and wear, which are common issues faced in various hydraulic systems. For instance, stainless steel is often preferred for its resistance to rust, especially in demanding environments. According to the Hydraulic Institute, the improper selection of materials can lead to up to 25% of system failures.

Another critical factor is the valve size. It's essential to match the size of the hydraulic check valve to the flow requirements of your system. Oversizing can lead to inefficiencies and increased operational costs, while undersizing may cause cavitation and decreased performance. In fact, research shows that optimizing valve size can improve energy efficiency by 10-15%.

Tip: Always consult with your equipment manufacturer or a hydraulic specialist to ensure the best fit for your system's specifications.

Additionally, pay attention to the valve's cracking pressure. This refers to the minimum pressure required to open the valve. Selecting a cracking pressure too high can restrict flow, while one too low might lead to unintended valve opening, compromising system integrity. Monitoring your application needs against hydraulic expectations can greatly enhance valve selection.

Tip: Use pressure drop calculations as a guideline to refine your choice, ensuring that your system operates smoothly and reliably.

When selecting a hydraulic check valve, the reliability of after-sales support can significantly influence your long-term satisfaction and operational efficiency. According to a recent industry report by the Fluid Power Society, nearly 40% of operators indicated that inadequate support from manufacturers led to operational downtimes, resulting in revenue losses of up to 30%. Thus, evaluating after-sales support is crucial in maintaining efficient hydraulic systems.

When selecting a hydraulic check valve, the reliability of after-sales support can significantly influence your long-term satisfaction and operational efficiency. According to a recent industry report by the Fluid Power Society, nearly 40% of operators indicated that inadequate support from manufacturers led to operational downtimes, resulting in revenue losses of up to 30%. Thus, evaluating after-sales support is crucial in maintaining efficient hydraulic systems.

Tip 1: Check the availability of technical support. A reliable supplier should offer prompt access to technical assistance via multiple channels—phone, email, or live chat. This accessibility can ensure that you have expert guidance when faced with installation or maintenance challenges.

Tip 2: Assess the warranty and service policies. Research indicates that manufacturers who provide comprehensive warranties and clear service policies tend to have higher customer satisfaction rates. A standard industry practice is to offer at least a one-year warranty on hydraulic components, with options for extended service agreements.

Tip 3: Investigate customer feedback and reviews. Gathering insights from current users through platforms such as industry forums and customer testimonials can provide a real-world perspective on the reliability and responsiveness of a manufacturer's support team. High ratings in after-sales service often correlate with fewer incidents of equipment failure and downtime.

Selecting the right hydraulic check valve is not just a matter of preference but a critical decision that can significantly impact operational efficiency. According to industry statistics, the right check valve can reduce operational downtime by up to 30%. This impressive figure highlights the valve's role in preventing backflow and ensuring the consistent flow of fluids in hydraulic systems.

When equipment runs smoothly with minimal interruptions, businesses can achieve substantial time and cost savings.

To maximize these benefits, it is essential to evaluate the specific needs of your hydraulic system. Factors such as pressure ratings, fluid compatibility, and installation requirements play a crucial role in choosing the right check valve. Neglecting these considerations can lead to failures and, consequently, increased downtime. By investing time in understanding your operational requirements and aligning them with the appropriate check valve technology, you can ensure reliability and longevity in your hydraulic systems.

This approach not only enhances productivity but also contributes to a safer working environment.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields