In the world of industrial automation, pneumatic valves play a crucial role in controlling air flow and pressure within various systems, significantly impacting overall operational efficiency. According to a report by MarketsandMarkets, the pneumatic equipment market is projected to reach USD 50 billion by 2025, emphasizing the growing importance of reliable pneumatic systems. However, the performance of pneumatic valves can deteriorate over time due to factors such as wear and tear, environmental conditions, and inadequate maintenance practices. Implementing a comprehensive maintenance checklist is essential for ensuring optimal performance and prolonging the lifespan of these critical components. This ultimate pneumatic valve maintenance checklist is designed to help operators and maintenance teams identify potential issues and implement best practices, ultimately leading to enhanced performance, reduced downtime, and cost savings for their operations.

When it comes to maintaining pneumatic valves, having the right tools and equipment is crucial for ensuring optimal performance and longevity. Start with a set of basic hand tools, including wrenches, screwdrivers, and pliers, which will allow you to easily disassemble and reassemble the components of your valves. Additionally, a torque wrench is essential for applying the correct amount of force when tightening fasteners, preventing damage that could lead to leaks or failure.

Incorporating diagnostic tools such as pressure gauges and flow meters can vastly improve your maintenance routine. These instruments enable you to monitor system performance, identify issues early, and make informed decisions on repairs. Don't forget about safety equipment, like gloves and goggles, which are vital when handling potentially hazardous materials or working in confined spaces. Investing in these essential tools and equipment can equip you to handle pneumatic valve maintenance with confidence, ensuring that your systems operate smoothly and efficiently.

When it comes to maintaining pneumatic valves, a thorough inspection is crucial to ensure optimal performance and longevity. Regular checks can help identify early signs of wear or malfunction, potentially saving significant costs in repairs and downtime. According to a report by the International Journal of Engineering and Technology, improper maintenance can decrease valve performance by up to 30%, leading to inefficiencies in pneumatic systems. Thus, a step-by-step guide to inspecting pneumatic valves is essential.

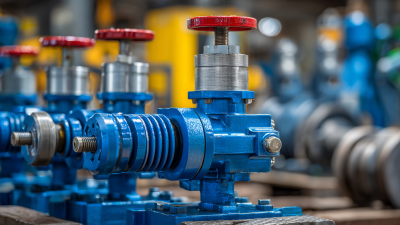

Begin with a visual inspection of external components, looking for signs of damage, corrosion, or leaks. As highlighted in the Pneumatics World Survey, nearly 20% of pneumatic valve failures are attributed to external wear, underscoring the importance of this step.

Next, check the actuator and spring functionality. Ensure that the actuator moves freely and that the spring returns to its original position without any obstructions. The American Society of Mechanical Engineers suggests that routine checks of actuator speed and response time can prevent issues that may arise from lag or delayed reactions, improving overall efficiency by as much as 25%.

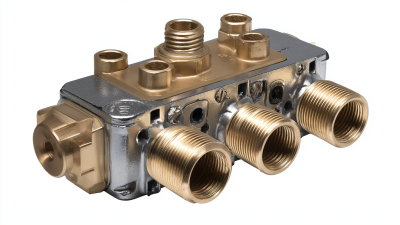

Finally, inspect internal components by disassembling the valve as needed, seeking wear on seats and seals, which can critically impact sealing performance.

A well-maintained pneumatic valve is crucial for ensuring optimal performance in any industrial system. However, issues can still arise that disrupt their functionality. Common problems include air leaks, which can lead to inefficiencies and increased energy costs. To identify air leaks, regularly inspect all seals and fittings, using soapy water to detect bubbling. If leaks are found, consider replacing gaskets or tightening fittings as necessary.

Another frequent issue is valve sticking, often caused by dirt or particulate buildup within the valve. This can hinder proper operation and response times. Regular cleaning and inspection are essential to prevent the accumulation of debris. Additionally, lubricating moving parts with the appropriate grease will help ensure smooth operation and extend the valve's lifespan. By staying vigilant and addressing these common issues, operators can maintain efficient and reliable valve performance in their pneumatic systems.

Maintaining pneumatic valves is crucial for ensuring optimal performance in various applications, particularly in environments where equipment is subject to adverse conditions, such as flooding. Best practices for cleaning and lubricating pneumatic valves can significantly enhance their durability and reliability. Regular cleaning is essential to remove contaminants that can impede valve function. A study indicated that routine maintenance can reduce the likelihood of system failures by up to 30%, underscoring the importance of proactive care.

Maintaining pneumatic valves is crucial for ensuring optimal performance in various applications, particularly in environments where equipment is subject to adverse conditions, such as flooding. Best practices for cleaning and lubricating pneumatic valves can significantly enhance their durability and reliability. Regular cleaning is essential to remove contaminants that can impede valve function. A study indicated that routine maintenance can reduce the likelihood of system failures by up to 30%, underscoring the importance of proactive care.

Lubrication is another critical aspect of pneumatic valve maintenance. Using the appropriate lubricants prevents wear and tear on moving parts and ensures smoother operation. Reports show that valves operating with proper lubrication can exhibit a lifespan increase of over 50%. In environments where valves may be submerged or exposed to moisture, selecting a lubricant with water-resistant properties is vital. This not only protects the metal components from corrosion but also ensures consistent performance even under challenging conditions. By adhering to these best practices, operators can significantly enhance the functionality and longevity of their pneumatic systems.

Regular maintenance of pneumatic valves is crucial for ensuring optimal performance and longevity. Establishing a maintenance schedule is the first step towards preventing potential failures and minimizing downtime in industrial operations. It is generally recommended to perform a comprehensive inspection at least once every three to six months, depending on the operational environment and the frequency of use. During these inspections, technicians should evaluate components for wear and tear, check for any air leaks, and ensure that the valve actuators are functioning correctly.

In addition to scheduled inspections, having a detailed maintenance checklist can significantly enhance the efficiency of the process. Key items on this checklist should include lubricating moving parts, tightening loose connections, and testing the responsiveness of each valve. Moreover, keeping an eye on any unusual noises or vibrations during operation can provide early warnings of impending issues.

By adhering to a regular maintenance schedule and utilizing a systematic checklist, facilities can ensure that their pneumatic valves operate at peak performance, leading to increased efficiency and reduced operational costs.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields