In the ever-evolving world of fluid power systems, the hydraulic flow control valve plays a critical role in optimizing performance and enhancing operational efficiency across various industries. According to a recent report by MarketsandMarkets, the global hydraulic valve market is expected to reach USD 20.4 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2%. This growth highlights the increasing reliance on precise flow control methods to improve machinery functionality and reduce energy consumption.

However, selecting the right hydraulic flow control valve can present challenges, including compatibility with existing systems and ensuring adequate response times. Understanding the common pitfalls associated with different valve types is essential for global buyers looking to navigate the complexities of hydraulic system design, thus ensuring sustainable and efficient operations in their applications.

When selecting hydraulic flow control valves, several key factors must be considered to ensure optimal performance and efficiency. First and foremost is understanding the specific application requirements. The flow rate, pressure ratings, and the characteristics of the hydraulic system play crucial roles in determining the type of valve suitable for the job. Choosing a valve that can handle the required flow without unnecessary pressure drops is essential to maintain the system's overall efficiency and longevity.

Another critical factor is the type of control mechanism used in the valve. There are various options, including manual, pneumatic, and electronic control valves, each serving different operational needs. For instance, pneumatic valves may offer faster response times for dynamic applications, while manual valves can provide simplicity and reliability for less variable tasks. Additionally, considering the materials and construction of the valve is vital, especially in harsh environments where corrosion resistance and durability are paramount. By carefully evaluating these factors, global buyers can make informed decisions that enhance their hydraulic systems' performance and reliability.

When selecting hydraulic flow control valves, many global buyers fall into common pitfalls that can lead to inefficiencies and increased costs.

One prevalent mistake is neglecting to account for the specific application requirements. According to a recent study by the International Fluid Power Society, improperly selected valves can increase energy consumption by up to 30%, driving up operational costs significantly. It’s crucial for buyers to analyze their specific system needs, including flow rates, pressure ranges, and environmental conditions, to ensure compatibility and efficiency.

Another frequent error is overlooking the importance of quality and manufacturer reputation. Data from the Fluid Power Engineering Association suggests that about 40% of valve failures are attributed to inferior products. Buyers must prioritize sourcing from reputable manufacturers who offer industry certifications and proven performance records. This not only guarantees reliability but also enhances overall system longevity. Understanding these common mistakes and making informed choices can lead to substantial improvements in performance and cost-effectiveness in hydraulic systems.

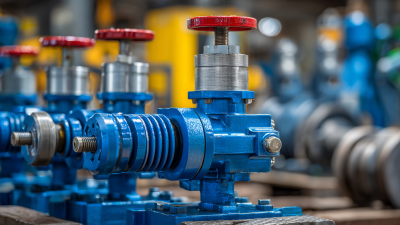

Hydraulic flow control valves play a vital role in managing the efficiency and performance of hydraulic systems. One of the top benefits of using these valves correctly is enhanced precision in fluid flow regulation. By controlling the amount of hydraulic fluid that passes through the system, operators can ensure that machinery and equipment function at optimal levels, reducing the risk of damage while improving overall productivity. This precision is particularly critical in applications requiring delicate movements or where timing is essential.

Another significant advantage of proper hydraulic flow control valve usage is improved energy efficiency. By allowing operators to fine-tune the flow rate, these valves minimize energy wastage, leading to lower operational costs. This benefit is increasingly important in today’s environmentally conscious landscape, where businesses are seeking ways to reduce their carbon footprint while maintaining performance. Additionally, effective flow control can extend the lifespan of hydraulic components by reducing unnecessary wear and tear, further contributing to cost savings and sustainability.

| Benefit | Description | Applicability | Performance Impact |

|---|---|---|---|

| Enhanced Control | Improves precision in flow rate adjustments, leading to better operational efficiency. | Manufacturing, Construction, Agriculture | Higher machinery performance and productivity. |

| Reduced Energy Consumption | Optimizes hydraulic fluid usage, which decreases overall energy costs. | Industrial Applications, Mobile Machinery | Cost savings and environmental benefits. |

| Extended Equipment Life | Minimizes wear and tear on components through stable hydraulic control. | Oil & Gas, Marine, Aerospace | Reduced maintenance costs and downtime. |

When selecting hydraulic flow control valves, it’s crucial to understand the various types available and their suitability for different applications. One of the most common types is the proportional flow control valve, which allows for precise adjustment of flow rates. These valves are ideal in situations where the speed of an actuator must be finely tuned, such as in robotics or precision manufacturing. Their ability to maintain consistent flow despite changes in pressure makes them a preferred choice for complex systems.

Another essential type is the pressure compensating flow control valve. This valve maintains a constant flow rate regardless of fluctuations in upstream pressure. This feature is especially valuable in hydraulic systems where load pressures can vary, as it ensures that performance remains stable under different conditions. Industries such as construction and agriculture often rely on these valves to manage power take-off systems and hydraulic drive systems effectively, enabling machinery to operate smoothly even in challenging environments.

Finally, flow restrictors serve as a basic yet effective option for applications where fluid flow needs to be limited without needing active control. They are widely used in simple hydraulic circuits, offering a cost-effective solution for reducing flow rates in less demanding tasks. By understanding the specific requirements of their applications, global buyers can make informed decisions to select the right hydraulic flow control valves, enhancing efficiency and performance in their operations.

When selecting hydraulic flow control valves, understanding and evaluating key performance metrics is crucial for global buyers. These metrics can significantly influence the efficiency and effectiveness of your hydraulic systems. First and foremost, flow rate capacity should be carefully assessed, as it dictates the volume of fluid the valve can handle. Ensuring that the valve can accommodate the flow requirements of your application is essential for optimal performance.

Additionally, responsiveness is a vital metric—look for valves with quick reaction times to changes in system pressure or demand. This can enhance system stability and reduce the risk of hydraulic shock.

Tips: Always consider testing the valve in a controlled environment to see how it reacts under various conditions. Another important aspect is durability; choose valves made from high-quality materials that can withstand harsh operating environments. Regular maintenance checks will also go a long way in preserving valve functionality and longevity, ensuring your hydraulic systems operate smoothly over time.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields