In the realm of fluid control systems, gate valves stand out as a fundamental component revered for their efficiency and reliability. As an industry expert, Dr. John Smith, a renowned hydraulic engineer, emphasizes the importance of gate valves in modern engineering, stating, “Gate valves are not just about controlling flow; they embody the essence of precision and performance in critical applications.” This insight sheds light on the versatility of gate valves, which are integral in various sectors ranging from water treatment facilities to oil and gas pipelines.

Understanding the different types of gate valves, their applications, and the benefits they offer can be pivotal for the success of your projects. Gate valves are designed to allow or prevent the flow of media, making them ideal for on/off services where minimal pressure drop is desired. Their robust construction and ability to handle high-pressure environments further underscore their significance. From rising stem gate valves to non-rising stem variants, each type caters to specific operational needs, ensuring that engineers can select the most suitable option for their requirements.

With increasing demands for efficiency and sustainability in industrial settings, the role of gate valves has never been more crucial. By delving into the various types of gate valves available, their applications in diverse industries, and the numerous benefits they bring, this guide aims to equip professionals with the knowledge to make informed decisions for optimal project outcomes.

Gate valves are essential components in various industrial applications, known for their capability to provide a tight seal and reliable on/off functionality. Understanding the different types of gate valves can help in selecting the appropriate valve for specific project needs.

Common types include wedge gate valves, parallel gate valves, and knife gate valves. Wedge gate valves are often used in high-pressure applications, thanks to their robust design. In contrast, parallel gate valves are ideal for low-pressure scenarios due to their ability to maintain a tight closure with less force. Knife gate valves excel in applications involving slurries, where their design allows for easy passage of solids while preventing blockages.

According to recent industry reports, the global market for gate valves is projected to grow significantly, driven by increasing demand from water supply and treatment, oil and gas, and manufacturing sectors. This growth highlights the importance of selecting the right type of gate valve to optimize operation and longevity.

Tips: When specifying a gate valve for your project, consider factors like the working pressure, temperature, and medium being controlled. Always ensure compatibility with the piping system and consider future maintenance needs. Proper installation and regular inspection can significantly enhance the lifespan of your valve system, avoiding costly downtime.

Gate valves are widely utilized across various industries due to their ability to provide a reliable on/off service for fluid flow. Their structure allows for smooth and uninterrupted flow when fully opened, making them ideal for applications where minimal pressure drops are essential. In the oil and gas industry, gate valves are commonly used to isolate sections of pipelines, ensuring safe maintenance operations while minimizing leakage risks. Similarly, in water treatment facilities, these valves help control water distribution and maintain system integrity.

Tips: When selecting a gate valve for your project, consider the fluid type, temperature, and pressure ratings to ensure optimal performance. Additionally, regular maintenance checks are crucial to prevent any operational failures that may arise from corrosion or buildup.

In the power generation sector, gate valves serve a significant role in steam and cooling water systems. Their robust design ensures they can handle high pressures and temperatures effectively. In firefighting systems, gate valves are essential for controlling water flow in and out of hydrants and main lines, providing quick access to water in emergency situations.

Tips: Always ensure that the gate valve is compatible with the materials of the piping system to prevent leaks or failures. It's beneficial to have spare valves on hand to facilitate quick replacements during urgent repairs.

Gate valves are essential components in fluid control systems, offering numerous advantages that enhance operational efficiency and reliability. Their primary function is to provide a straight-line flow path, which minimizes turbulence and pressure drops when fully opened. This makes gate valves an excellent choice for applications requiring minimal flow resistance, such as in water supply and drainage systems. When these valves are either fully opened or closed, they do not obstruct the flow, ensuring that the performance of the system is not compromised.

Gate valves are essential components in fluid control systems, offering numerous advantages that enhance operational efficiency and reliability. Their primary function is to provide a straight-line flow path, which minimizes turbulence and pressure drops when fully opened. This makes gate valves an excellent choice for applications requiring minimal flow resistance, such as in water supply and drainage systems. When these valves are either fully opened or closed, they do not obstruct the flow, ensuring that the performance of the system is not compromised.

Another significant benefit of using gate valves is their durability and longevity. Constructed from robust materials, these valves can withstand harsh environmental conditions, making them ideal for both industrial and residential settings. Furthermore, gate valves require less maintenance compared to other types because they are typically equipped with a simple design and few moving parts. This reliability translates into lower operational costs over time, allowing project managers to allocate resources more effectively. In summary, the advantages of gate valves in fluid control systems include efficient fluid flow, minimal maintenance needs, and enhanced durability, making them a preferred choice for various projects.

When selecting the right gate valve for your project, several key factors must be taken into account to ensure optimal performance and longevity. Firstly, understanding the fluid type and its properties is crucial. Different fluids exert varying pressures and may involve corrosive elements that require specific materials for the valve body and sealing components. For instance, choosing a valve made from stainless steel may be imperative for applications involving corrosive substances, while a carbon steel valve might suffice for less aggressive scenarios.

Secondly, the pressure and temperature conditions of the application play a significant role in valve selection. Gate valves are designed to operate under specific pressure ratings, and it’s vital to match these ratings with the working conditions of your project. Additionally, factors such as the valve size and connection type must be aligned with existing piping to ensure compatibility and prevent potential leaks. Lastly, maintenance considerations should not be overlooked. Opt for gate valves that allow for easy access for routine inspections and servicing, which can significantly reduce downtime and ensure a reliable operation throughout the lifespan of the project.

| Valve Type | Application | Benefits | Key Considerations |

|---|---|---|---|

| Wedge Gate Valve | Water Supply Systems | Low fluid friction, good sealing | Requires full open/close operation |

| Parallel Gate Valve | Oil and Gas Pipelines | Excellent flow control, compact | Sensitive to dirt; must be kept clean |

| Knife Gate Valve | Slurry and Wastewater Treatment | Able to handle viscous fluids | Not suitable for throttling |

| Rising Stem Gate Valve | Industrial and Commercial Plumbing | Visual indication of open/closed status | Larger space required for operation |

| Non-Rising Stem Gate Valve | Underground Installations | Space-efficient, easier installations | Difficult to gauge valve position |

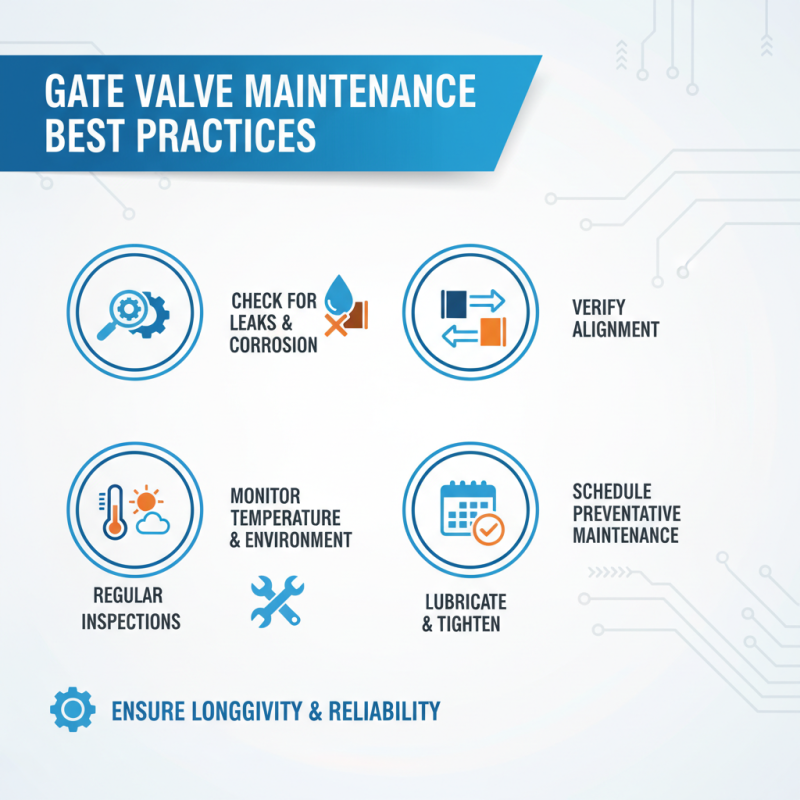

To ensure the longevity and performance of gate valves, implementing maintenance best practices is essential. Regular inspections should be conducted to identify any signs of wear or damage that may affect functionality. Checking for leaks, corrosion, and proper alignment will help in early detection of potential issues. It is important to monitor the operating environment as well, since factors such as temperature fluctuations and exposure to environmental elements can influence the valve's condition.

Lubrication plays a vital role in the maintenance of gate valves. Applying appropriate lubricants to the stem and seats helps prevent sticking and ensures smooth operation. It is advisable to follow manufacturer guidelines regarding the frequency and type of lubrication. Furthermore, exercising the valve periodically—opening and closing it at regular intervals—will help prevent the valve from becoming stuck due to corrosion or debris accumulation. Maintaining a clean valve environment by removing any external contaminants also contributes to optimal performance.

Finally, maintaining proper documentation of maintenance activities is crucial. Keeping a detailed log of inspections, repairs, and part replacements allows for tracking the valve’s history and performance over time. This record can provide valuable insights into the valve's condition and any recurring issues, facilitating informed decision-making for future maintenance tasks. By adhering to these best practices, the durability and efficiency of gate valves can be significantly enhanced, leading to improved project outcomes.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields