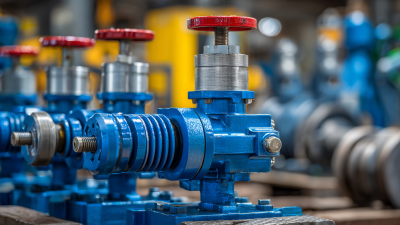

In the rapidly evolving landscape of modern industrial applications, the role of actuator valves has become paramount. According to a recent report by MarketsandMarkets, the global market for industrial valves, including actuator valves, is projected to reach $85.5 billion by 2027, growing at a CAGR of 5.3% from 2022 to 2027. Actuator valves are critical components in automating processes, providing precision control over flow, pressure, and temperature in various industries, from oil and gas to water treatment and manufacturing. As industries strive for increased efficiency and reliability, understanding the functionality of actuator valves not only enhances operational performance but also contributes to overall system safety and sustainability. This blog delves into the intricate workings of actuator valves, exploring their designs, types, and applications, while offering valuable tips for maximizing their effectiveness in contemporary industrial environments.

Actuator valves are critical components in modern industrial applications, primarily serving to regulate fluid flow and enhance process efficiency. By converting a control signal into mechanical movement, these valves ensure precise handling of fluids, minimizing waste and maximizing output. In industries where both safety and efficiency are paramount, actuator valves play a vital role. They not only streamline operations but also significantly reduce energy consumption, which is essential for cost-effective production.

Actuator valves are critical components in modern industrial applications, primarily serving to regulate fluid flow and enhance process efficiency. By converting a control signal into mechanical movement, these valves ensure precise handling of fluids, minimizing waste and maximizing output. In industries where both safety and efficiency are paramount, actuator valves play a vital role. They not only streamline operations but also significantly reduce energy consumption, which is essential for cost-effective production.

Tips for selecting the right actuator valve include considering the specific process requirements, such as pressure, temperature, and the type of fluid being controlled. Additionally, it's essential to assess the communication protocol and compatibility with existing control systems. Regular maintenance and calibration are also crucial to ensure optimal performance and to prevent unexpected downtime.

Implementing actuator valves can also lead to better safety standards within the workplace. Automated control reduces the risk associated with manual handling, thus creating safer environments for operators. Always keep in mind the importance of choosing reliable manufacturers and investing in quality products, as these choices can influence overall operational efficacy and longevity of the equipment.

In the realm of modern industrial applications, actuator valves play a pivotal role in enhancing operational efficiency and reliability. These valves are instrumental in controlling the flow of fluids, with electric, pneumatic, and hydraulic actuator valves being the most prominent types. According to a recent report by MarketsandMarkets, the global actuator market is expected to reach $33.73 billion by 2027, growing at a CAGR of 6.2%. This growth underscores the increasing reliance on automated valve control systems in industries such as oil and gas, water treatment, and manufacturing.

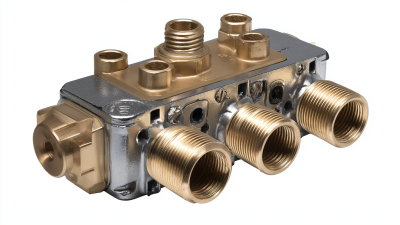

Electric actuator valves are favored for their precision and ease of integration with digital control systems, ideal for applications requiring high accuracy, such as pharmaceuticals and food processing. Pneumatic actuators, on the other hand, offer rapid response times and robust performance in environments with fluctuating temperatures, making them suitable for chemical processing. Meanwhile, hydraulic actuator valves, known for their ability to handle heavy loads, are extensively used in sectors like mining and heavy equipment operations. The strategic adoption of these actuator valve types signifies an ongoing trend toward automation and enhanced process control in modern industrial systems.

| Type of Actuator Valve | Functionality | Applications | Common Features |

|---|---|---|---|

| Electric Actuator Valve | Converts electrical energy into mechanical motion to open or close the valve | Water treatment, HVAC systems, Oil and gas pipelines | High precision, Remote control, Low maintenance |

| Pneumatic Actuator Valve | Uses compressed air to move the valve mechanism | Food processing, Chemical manufacturing, Paper production | Fast operation, High force, Compact design |

| Hydraulic Actuator Valve | Utilizes hydraulic fluid pressure to operate the valve | Heavy machinery, Aerospace, Marine applications | High torque, Robust construction, Suitable for heavy loads |

| Solenoid Valve | Electromagnetically actuated valve for quick on/off operation | Automotive systems, Irrigation, Robotics | Compact, Fast response time, Easy installation |

Actuator valves play a pivotal role in enhancing the operational effectiveness of modern industrial applications by facilitating precise control over fluid flow. According to a report by Research and Markets, the actuator valve market is expected to grow by over 7% annually, reflecting the increasing demand for automation and efficiency in various sectors. These valves contribute significantly to performance metrics, such as response time and energy consumption, which are critical for optimizing industrial processes.

One of the key performance indicators for actuator valves is their accuracy in flow regulation. A study by the International Society of Automation indicates that advanced actuator valves can improve flow control accuracy by up to 95%, thereby minimizing wastage and ensuring resource efficiency.

Furthermore, in facilities employing actuator valves, it has been observed that operational downtime decreases by approximately 30%, due to the valves' reliability and quick response to control signals. This reduction in downtime not only boosts productivity but also lowers maintenance costs, making actuator valves essential for achieving high operational effectiveness in today's competitive industrial landscape.

The integration of smart technologies is revolutionizing the functionality of actuator valves in industrial automation. As industries increasingly embrace Industry 4.0 principles, the market for smart actuator valves is projected to grow at a CAGR of 7.5%, reaching an estimated value of $5.1 billion by 2027, according to a recent report by MarketsandMarkets. These advancements enhance monitoring capabilities, allowing for real-time data collection and increased operational efficiency.

One of the key benefits of smart actuator valves is their ability to communicate with other smart devices within the industrial ecosystem. This interconnectivity facilitates predictive maintenance, reducing downtime and repair costs by up to 20%. Implementing condition-based monitoring can also extend the lifespan of these valves, optimizing resource allocation within manufacturing processes.

**Tip:** When selecting actuator valves, ensure that they are compatible with your existing smart systems to maximize their efficiency. Additionally, consider solutions that support advanced analytics for better decision-making in valve management. By leveraging these technologies, businesses can enhance automation strategies and improve overall productivity.

This chart illustrates the distribution of various actuator valve types used in industrial automation. It highlights the adoption of smart technologies in actuator valves, which is shaping the future of automation.

In modern industrial applications, actuator valves play a crucial role in enhancing operational efficiency while minimizing environmental impact.

Given the pressing need to reduce gas flaring and venting, the reliability of these valves directly correlates with downtime reduction in production processes. The oil and gas industry has faced significant scrutiny over methane emissions, which soared to approximately 120 million tonnes in 2023. This situation emphasizes the urgent requirement for advanced valve technologies that can mitigate emissions while ensuring smooth operations.

Recent investments in cutting-edge valve technologies are indicative of the industry's commitment to sustainability. By implementing proactive maintenance schemes for electric actuator valves, companies can achieve better fault detection, diagnosis, and prediction. This not only improves valve reliability but also significantly decreases the chances of unexpected downtimes.

As firms strive to balance production demands with environmental responsibilities, the role of advanced actuator valves becomes increasingly vital for sustainable growth in the industry.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields