Choosing the right pneumatic control valve is crucial for any system's efficiency and performance. John Smith, a renowned expert in the pneumatic industry, once said, "The right valve can make or break a system." This statement highlights the importance of selection in pneumatic applications.

Different systems have unique requirements. A valve that works well in one setup may fail in another. This creates challenges for engineers and technicians. Understanding the specifications is key. Factors like pressure, flow rate, and media type can greatly affect performance.

Moreover, the complexity of pneumatic control valves can lead to mistakes. It's crucial to analyze the specific application thoroughly. Simple shortcuts can result in significant issues. By taking the time to evaluate, users can avoid costly errors and ensure optimal operation.

Pneumatic control valves play a crucial role in industrial systems. They regulate the flow of compressed air, ensuring efficient operation. Understanding their function can help you make informed choices. According to a report from the International Society of Automation, poor valve selection can lead to operational inefficiencies, costing industries significant amounts annually.

Choosing the right valve isn't always straightforward. Many factors come into play. Flow rate, pressure, and temperature specifications need careful consideration. A mismatch in any of these parameters can cause failures. Studies indicate that almost 30% of plant downtime is linked to valve malfunction, emphasizing the importance of making the right choice.

Installation is another area that often requires reflection. Improper alignment can lead to leaks or slow responses. Furthermore, regular maintenance is essential. It's common for users to overlook this aspect. Neglecting maintenance can reduce valve lifespan, which is regrettable. In essence, the right pneumatic valve contributes to smoother operations and minimized costs. Yet, without due diligence, that potential remains unfulfilled.

Choosing the right pneumatic control valve is crucial for system efficiency. Several key factors affect your decision. The flow rate required by your application is one of them. It determines whether the valve can perform effectively. Also, consider the pressure levels involved in your system. Make sure the valve can handle them without any issue.

Another important factor is the valve's response time. In many applications, a quick response is necessary. Look for valves with low hysteresis. This will reduce errors in control. Remember that the environment matters too. Corrosive or extreme conditions can impact valve performance. Select materials that can withstand your specific environment.

Tips: Test the valve's compatibility before installation. Sometimes, what looks right initially may not work perfectly. Monitor its performance regularly. If you notice irregularities, be prepared to reassess your choice. It’s essential to stay flexible and adapt. Finding the perfect valve may require a few tries.

This chart illustrates the key factors to consider when selecting pneumatic control valves, rated on a scale of 1 to 10 based on their importance. Size, material, and pressure rating are among the most critical aspects to evaluate. Understanding these factors will help ensure optimal performance and longevity for your pneumatic systems.

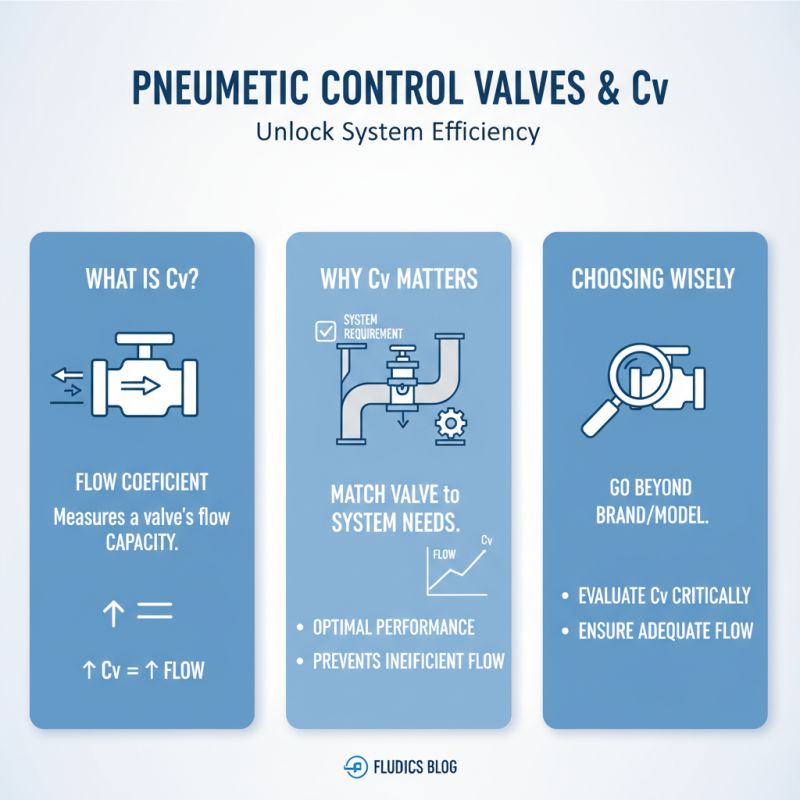

Choosing the right pneumatic control valve isn't just about the brand or the model. It's about understanding the flow coefficient, known as Cv. This value indicates how much fluid can flow through a valve at a given pressure drop. A higher Cv means more flow capacity. Evaluating this helps you select a valve that meets your system's requirements.

When assessing Cv, consider the application type. Is it for gases or liquids? The properties of the medium play a crucial role. For example, compressible fluids behave differently than incompressible ones. You might find that the calculated Cv doesn't fit well in real-world scenarios. This mismatch often leads to performance issues.

It's also vital to account for installation conditions. Factors like pipe size and length affect flow dynamics. Oversizing the valve can lead to inefficiencies and unstable operation. Conversely, undersized valves may restrict flow and cause pressure drops. Keep these nuances in mind. Evaluating Cv is not a one-time task. Regular reviews and adjustments are key to maintaining optimum performance.

Material compatibility is crucial in selecting pneumatic control valves. The valve must withstand the specific media it encounters. For instance, if the system uses abrasive materials, the valve seat and body materials should be highly resistant to wear. According to a report from the Flow Control Industry, nearly 30% of valve failures result from material incompatibility.

Consider the chemical properties of the media. Corrosive substances can degrade metals over time. A study found that 60% of component failures in pneumatic systems stem from poor material choices. Choosing suitable materials reduces risks. For example, using stainless steel for water or air is often a safe bet.

However, mistakes happen. Some engineers overlook the temperature limits of materials. Ignoring thermal expansion can lead to leaks or failures. It's essential to reference charts and guidelines. A well-informed choice mitigates these risks. Valve selection requires careful thought, aiming for a long-term solution.

When selecting a pneumatic control valve, understanding pressure and temperature ratings is crucial. These ratings dictate a valve's ability to withstand operational conditions. In a recent industry report, over 70% of valve failures stem from incorrect pressure tolerances. This highlights the importance of vigilant assessment.

Temperature ratings also play a significant role. They determine the material stability under high or low conditions. For instance, valves exposed to extreme temperatures can degrade faster. A notable study found that improperly rated valves experienced a 30% increase in maintenance costs. This statistic urges one to thoroughly evaluate temperature ratings to ensure longevity and reliability.

It’s essential to remember that both factors work together. High pressure can affect a valve’s temperature resistance. The relationship is complex, and sometimes misunderstood. Regular audits and predictive maintenance can help mitigate risks. However, underestimating these ratings often leads to operational failures. This reality reminds us to reflect on design choices and operational protocols regularly.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields