In the ever-evolving landscape of industrial operations, the integration of air valve solutions has emerged as a pivotal strategy for enhancing efficiency. According to a recent report by the Pneumatic Institute, the adoption of advanced air valve technology can lead to a reduction in energy consumption by up to 20%, significantly impacting operational costs and overall productivity. These improvements stem from the precision and reliability of modern air valves, which optimize the control of air flow in various applications ranging from manufacturing to HVAC systems. As industries look to boost their competitive edge, understanding the benefits of air valves is essential for decision-makers aiming to leverage innovative solutions that drive efficiency and sustainability. With continuous advancements in this field, air valve solutions not only promise enhanced performance but also contribute to a greener future through reduced waste and lower emissions.

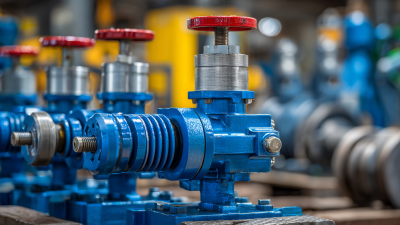

Air valve solutions are essential components in various industrial applications, offering significant advantages that enhance system efficiency. One of the key features of these solutions is their ability to regulate airflow effectively, ensuring optimal performance in pneumatic systems. By controlling the pressure and flow of air, air valves minimize energy wastage and facilitate smoother operations, which can lead to substantial cost savings over time.

In addition to energy efficiency, air valves also provide enhanced reliability and maintenance ease. With advanced materials and designs, these valves are built to withstand harsh conditions, reducing the likelihood of failures and downtime. Furthermore, they often come with user-friendly interfaces that allow for quick adjustments and troubleshooting, minimizing the need for specialized skills. These combined benefits not only improve operational efficiency but also extend the lifespan of equipment, making air valve solutions a smart investment for businesses looking to optimize their processes.

In the realm of industrial applications, efficiency is paramount, and air valves play a crucial role in achieving optimal performance. These devices regulate the flow of air within various systems, ensuring smooth operation and minimal energy consumption. By precisely controlling air pressure and flow rates, air valves help maintain the balance that is vital for the performance of pneumatic actuators, conveyors, and other equipment. This efficiency not only enhances productivity but also significantly reduces operational costs.

Moreover, air valves contribute to improved safety in industrial environments. By preventing overpressure situations and maintaining proper airflow, they protect machinery from potential damage and minimize the risk of accidents. Additionally, modern air valve solutions often incorporate advanced technologies such as sensors and smart controls, allowing for real-time monitoring and data analysis. This integration facilitates proactive maintenance approaches, further enhancing overall system reliability and efficiency. As industries continue to embrace automation and smart technologies, the importance of air valves in streamlining processes and boosting operational efficiency cannot be overstated.

When selecting the right air valve for your needs, it's essential to consider several key factors that can enhance operational efficiency.

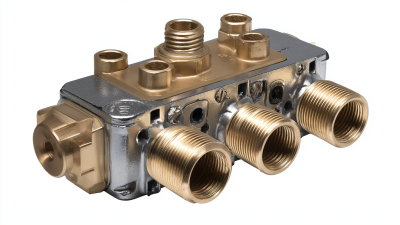

Begin with evaluating the application requirements; the type of air valve should align with the specific function it serves within your system, whether it be for controlling airflow, regulating pressure, or providing safety measures. Understanding the working environment, including temperature, pressure, and corrosive elements, will further guide you towards a suitable product that can withstand these conditions, ensuring longevity and reliability.

When selecting the right air valve for your needs, it's essential to consider several key factors that can enhance operational efficiency.

Begin with evaluating the application requirements; the type of air valve should align with the specific function it serves within your system, whether it be for controlling airflow, regulating pressure, or providing safety measures. Understanding the working environment, including temperature, pressure, and corrosive elements, will further guide you towards a suitable product that can withstand these conditions, ensuring longevity and reliability.

Next, the sizing of the air valve plays a critical role in performance. Take accurate measurements of your existing systems to determine the appropriate diameter and flow rate that will optimize efficiency. Additionally, consider the actuation method—manual, electric, or pneumatic. Each option possesses unique advantages and may contribute differently to workflow dynamics. Lastly, don’t overlook maintenance and compatibility; choose a valve that is easy to maintain and integrates seamlessly with your existing infrastructure to minimize downtime and maximize productivity.

By following this checklist, you can make informed decisions that will enhance your overall operational efficiency.

When it comes to air valve systems, troubleshooting common issues is essential for maintaining optimal performance in various applications, from commercial vehicles to HVAC systems. Air system failures can be attributed to a range of issues, including leakage, blockage, or component wear. For instance, technicians often face difficulties with pneumatic valves that can lead to inadequate braking or system inefficiency. Identifying the underlying problem is the first step; look for visible leaks or listen for hissing sounds that may indicate air escaping from compromised seals.

Another common issue arises when the air supply pressure drops below the required level, leading to diminished functionality. This can often be addressed by checking the air compressor for faults or inspecting the entire air supply line for any signs of damage. Regular maintenance, such as cleaning filters and ensuring connections are secure, can help prevent these issues. In addition, being familiar with the operational thresholds of each component will empower technicians to effectively troubleshoot problems before they escalate, ensuring a smoother, more efficient operation of the entire air valve system.

When it comes to optimizing your business operations, the investment in air valve solutions may seem daunting at first, but a thorough cost-benefit analysis reveals significant advantages. Air valves enhance system efficiency, reduce energy consumption, and promote safety in industrial settings. By streamlining air management, companies can minimize operational costs and improve overall productivity.

**Tip:** Regular maintenance of air valves is crucial. Schedule inspections to ensure they're functioning correctly, as even minor leaks can lead to substantial energy losses over time.

Investing in high-quality air valve solutions can also prevent costly downtime due to equipment failure, making it a wise long-term strategy. When evaluating potential options, consider the return on investment (ROI) based on performance improvements and potential savings.

**Tip:** Leverage data analytics to track valve performance and identify areas for improvement. This data will be invaluable in justifying the initial investment and demonstrating the value added to your operation.

Accreditations

ISO 9001 Quality Management

HSE Management Compliant

Products and services comply with relevant Australian (AS) and international (ISO, etc.) Standards.

"*" indicates required fields